I've brewed an English Bitter to the exact same recipe twice now. Both times, the estimated ABV was 3.6% in BeerSmith -- this matches the beer I'm 'cloning'. I have consistently hit 4.5% with both batches. I want to explore my options for the next batch, to bring it down to the desired 3.6%.

The yeast I'm using is Ringwood WPL005 from a home made slant. BeerSmith shows this as having a max attenuation of 74% and this indeed matches the characteristics listed on White Labs for this yeast: https://www.whitelabs.com/yeast-bank/wlp005-british-ale-yeast

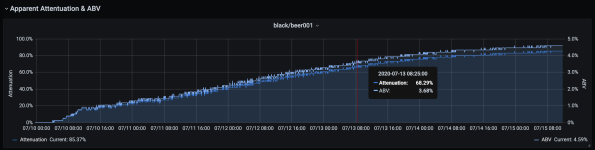

Currently, in the Primary fermenter, 6 days into fermentation I have 85% attenuation.

Looking at my graph (attached) I see that I hit my target ABV 2 days ago when the attenuation was at 65%.

What should I do for my next batch to try and get the ABV to ~3.5% ?

Is the issue entirely with the high attenuation?

Should I reduce my grain bill?

Should I adjust the yeast in the tab so that the max attenuation is 85% ? In doing so, will the grain bill dynamically adjust to ensure 3.5% is hit?

If I transfer into Secondary when the ABV is close to 3.5% next time, will this slow the fermentation enough to stall it around my desired ABV?

The yeast I'm using is Ringwood WPL005 from a home made slant. BeerSmith shows this as having a max attenuation of 74% and this indeed matches the characteristics listed on White Labs for this yeast: https://www.whitelabs.com/yeast-bank/wlp005-british-ale-yeast

Currently, in the Primary fermenter, 6 days into fermentation I have 85% attenuation.

Looking at my graph (attached) I see that I hit my target ABV 2 days ago when the attenuation was at 65%.

What should I do for my next batch to try and get the ABV to ~3.5% ?

Is the issue entirely with the high attenuation?

Should I reduce my grain bill?

Should I adjust the yeast in the tab so that the max attenuation is 85% ? In doing so, will the grain bill dynamically adjust to ensure 3.5% is hit?

If I transfer into Secondary when the ABV is close to 3.5% next time, will this slow the fermentation enough to stall it around my desired ABV?