Oginme

Grandmaster Brewer

I recently purchased an Anvil Foundry 6.5 Gallon all-in-one brewing system and thought I would walk you all through the process I use to set up an equipment profile.

I plan on using this system to brew a 10 liter batch into the fermenter, with 11+ liters finished at the end of the boil. My plan is to refine this once I get a feel for how much I can successfully drain (wort) using the rotating dip tube.

I unboxed the unit and put the system together, cutting the tubing for the drain and recirculation pump to appropriate length. Hooking up the hose and placing 3 liters of water into the system, I fired up the pump to test the recirculation and to look for any signs of leaks in the system and recirculation tubing. I also realigned the head of the pump to point the outlet directly up.

The system was drained out to the lowest setting I can orient the dip tube and this left (by difference) 320 ml of water left in the system. This represents the lowest value the loss to trub and chilling can be set. There was an additional 40 ml of water left in the lines once everything had been pumped out and the lines drained.

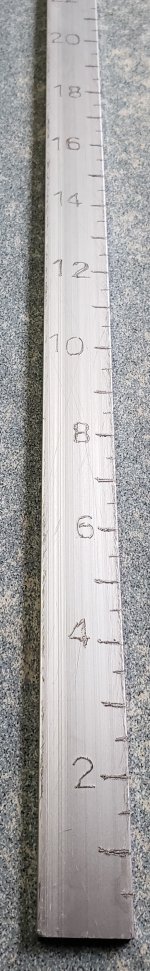

The next step was to make a calibrated dip stick for the device. Unfortunately the machine has engraved markings starting at 2.5 gallons/10 liters. I like to double check any factory markings anyway, but this also gave me the opportunity to establish markings at every half liter. MY method for this is to take a piece of aluminum stock (3/4? side by ?? thick) and coat one side with food coloring. I allow this to dry and then using a calibrated volumetric beaker, I add water one liter at a time, using the dip stick to measure the depth and then marking where the water level on the aluminum stick is with a permanent marker before engraving the lines and volume indicators into the aluminum stock.

Since the system is controlled for temperature and I am using recirculation during the mash, getting the actual weight of the Anvil Foundry is not as critical. I do, however want my strike temperature to get me pretty close to the mash temperature I desire from the dough in, so I will get the gross weight of the Anvil vessel with the basket.

I plan on using this system to brew a 10 liter batch into the fermenter, with 11+ liters finished at the end of the boil. My plan is to refine this once I get a feel for how much I can successfully drain (wort) using the rotating dip tube.

I unboxed the unit and put the system together, cutting the tubing for the drain and recirculation pump to appropriate length. Hooking up the hose and placing 3 liters of water into the system, I fired up the pump to test the recirculation and to look for any signs of leaks in the system and recirculation tubing. I also realigned the head of the pump to point the outlet directly up.

The system was drained out to the lowest setting I can orient the dip tube and this left (by difference) 320 ml of water left in the system. This represents the lowest value the loss to trub and chilling can be set. There was an additional 40 ml of water left in the lines once everything had been pumped out and the lines drained.

The next step was to make a calibrated dip stick for the device. Unfortunately the machine has engraved markings starting at 2.5 gallons/10 liters. I like to double check any factory markings anyway, but this also gave me the opportunity to establish markings at every half liter. MY method for this is to take a piece of aluminum stock (3/4? side by ?? thick) and coat one side with food coloring. I allow this to dry and then using a calibrated volumetric beaker, I add water one liter at a time, using the dip stick to measure the depth and then marking where the water level on the aluminum stick is with a permanent marker before engraving the lines and volume indicators into the aluminum stock.

Since the system is controlled for temperature and I am using recirculation during the mash, getting the actual weight of the Anvil Foundry is not as critical. I do, however want my strike temperature to get me pretty close to the mash temperature I desire from the dough in, so I will get the gross weight of the Anvil vessel with the basket.